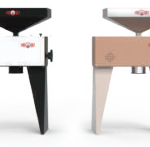

MALT MILLS

To ensure quality malt crushing, the brewer must be equipped with quality and reliable equipment, on which he can rely at any time.

CRIQUET malt mills meet the specific requirements of brewers and distillers:

– Very precise grinding adjustment

– Hopper suitable for malt bags

– Robust and durable mechanics

TECHNICAL FEATURES OF OUR MALT MILLS

Flow rate from 100kg/h to 1500kg/h

Steering handwheel

calibration

(0.10mm accuracy)

Cylinders

steel,

cast-iron

or stainless steel

Powertrains

230V or 400V

0.37KW to 4KW

jgiugui

Strapping for

filling of the

milling bags

Castors of

displacement

Models

customizable

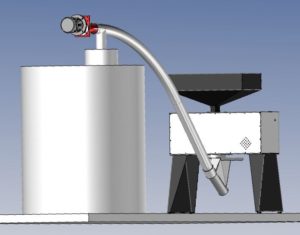

CONVOYER SCREWS

On study, we provide conveyor screws adapted to your brewery.

To optimize the transport of the grind to the brewing tank and the supply of the malt mill.

Criquet's Company

The first CRIQUET mills and crushers were designed and manufactured in the 50s near Lyon (France).

In the 90s, manufacturing moved closed to Toulouse (France).

Today, our independent company is proud to continue to design and manufacture new models of malt mills, for beer brewers and whisky distillers.

Design and manufacture are entirely carried out in our workshop in South of France.

THE WORKSHOP

We are specialized in the manufacture of malt mills.

Our workshop team is motivated by the desire to bring quality that meets our customers’ expectations

Innovation, quality and sustainability are our watchwords.

What brewers say about our malt mills

Breweries equipped with Criquet mills

Contact us to be put in contact with a brewery already equipped near you

Search Location

News

Convoyer screw

Let’s meet at the brewery exhibition in Nancy

Partner

Receive the documentation